MBL | Barrel Washing Machine

Description

The barrel is suspended and powered by V-belts. The barrel chamber is separated from the out-feed elevator by an adjustable screen. A fresh water rinse bar can be mounted above the out-feed elevator and in the water tank (optional).

Automated washing process - self-cleaning through sluice funnels fitted with pneumatic valves (requires external source of compressed air); automatic water level control system. The machine features a user-friendly touch screen which makes the operation smooth and easy (optional).

The standard barrel is made of perforated sheet with the perforations diameter of 10mm. The MBL Barrel Washer is available in left- or right-hand version (position of the washout doors and control panel).

Additional options:

- Barrel: stainless steel, perforated sheet or moulded slats

- Barrel working speed regulated by an inverter

- Additional fresh water sprinkler mounted in the barrel

- Regulated gate with electric control (optional) instead of a liftable out-feed screen

Main features:

- V-belt drive ensures very quiet and smooth operation

- Perforated drivers on the conveyor belt leave more water inside the tank

- The barrel is powered by a helical motoreducer which can last 10 times longer than an intersecting axis gear

- Waste water sluice valve (ø50, ø75 or ø100mm)

- Anti-corrosion protection - sandblasted construction covered with two layers of hammer-effect paint

MBL.WS version with a brush roll unit is also available.

The MB and MBL washers feature an active brush roll unit Ø200mm (powered by a motoreducer) and a brush lining mounted in the barrel.

Specification

| model | MBL-820 | MBL-825 | MBL-1030 | MBL-1040 | MBL-1230 | MBL-1240 | |

| max. productivity (carrot | potato) | [t/h] | 3,0 | 5,0 | 5,0 | 8,0 | 7,0 | 11,0 | 9,0 | 14,0 | 12,0 | 20,0 | 15,0 | 25,0 |

| barrel (Ø|length) | [m] | 0,8 | 2,0 | 0,8 | 2,5 | 1,0 | 3,0 | 1,0 | 4,0 | 1,2 | 3,0 | 1,2 | 4,0 |

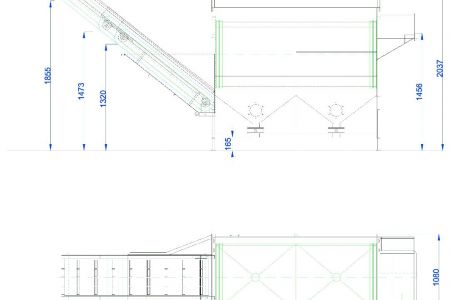

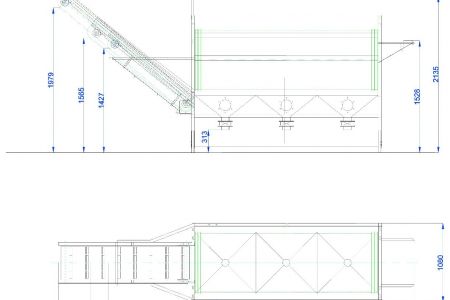

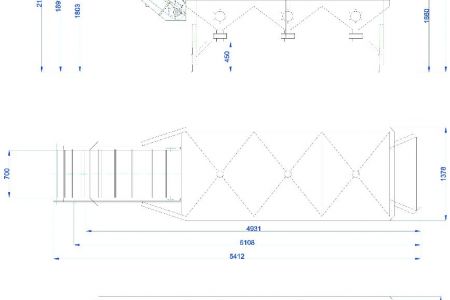

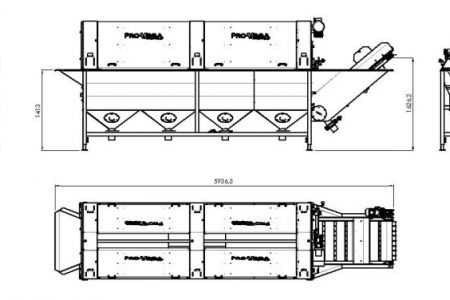

| overall length | [mm] | 3750 | 4250 | 5200 | 5950 | 5900 | 6900 |

| water tank capacity (+/-30%) | [m³] | 1,0 | 1,1 | 1,5 | 1,8 | 2,4 | 2,8 |

| installed capacity | [kW] | 1,75 | 1,75 | 2,05 | 2,75 | 4,5 | 4,5 |

Gallery

MBL-820

MBL-825

MBL-1300

MBL-1400